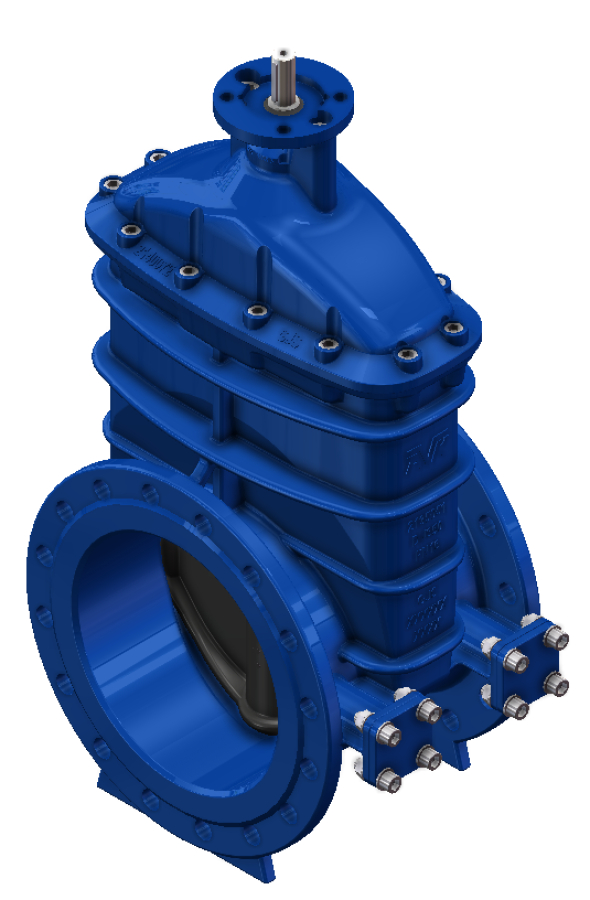

AVK GATE VALVE FOR ACTUATION, PN 16, CTC

DN50-400. Product upgraded see 21/37-001 and 21/79-001

Mamoun Humayra

Water Product Manager

Resilient seated gate valve to BS EN 1074-2 for water and waste water. Temperature range: -10° C to +70° C. Max 10% solid matter. Insulation essential for temperatures of 0° and below.

The Series 21/78 is a resilient seat, wedge gate valve with an ISO mounting gland flange for the safe and cost effective fitting of gearboxes and actuators. Suitable for use with water and neutral liquids, to a maximum temperature of +70°C.

| Variant 21/78-001 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| DN: | DN65 - DN400 |

| PN: | PN 16 |

Features

- ISO flange gland version for gearbox and actuator mounting.

- Ductile iron wedge, fully vulcanized with EPDM rubber.

- O-ring stem seals replaceable under pressure.

- Corrosion resistant construction, ductile iron coated with WRAS approved epoxy coating Blue RAL 5017, to 250 microns min. Holiday free in accordance with WIS 04-52-01.

- Body, bonnet and gland bolts sealed with hot melt.

- Lifting bars - see safety note below.

- Sizes DN50-150 have ISO mounting flange F10 only.

- Sizes DN200-400 ISO mounting flange is double drilled F10/F14.

- Options:

- Electric actuation.

- Bevel or spur gearboxes.

- Alternative flange drilling.

- Safety Note:

- The valves now accommodate lifting bars for the safe handling of valves. These lifting bars are rated to the weight of the bare valve and stem cap (where fitted) only and should not be utilised if the valve is fitted with pipe, mechanical pipe joints, gearboxes, actuators or any other external fitment. AVK will not accept any responsibility for loss or damage if the lifting bars are not used in strict accordance with this guidance.

Downloads

Datasheet

Related Datasheets

Installation, Operation & Maintenance

Price list

Reference nos. and dimensions:

Scroll for more info

| Ref. no. | DN mm |

Operating Direction |

H3 mm |

H mm |

H1 mm |

L mm |

D2 mm |

W mm |

Torque Nm |

Theoretical weight/kg |

|---|---|---|---|---|---|---|---|---|---|---|

| 21-065-78-0140069 | 65 | CTC | 341 | 228 | 248 | 190 | 20 | 185 | 60 | 13 |

| 21-250-78-0140069 | 250 | CTC | 776 | 576 | 531 | 330 | 23 | 400 | 120 | 84 |

| 21-250-78-1140069 | 250 | CTO | 776 | 576 | 531 | 330 | 23 | 400 | 120 | 84 |

| 21-300-78-0140069 | 300 | CTC | 880 | 652 | 607 | 356 | 23 | 455 | 100 | 122 |

| 21-300-78-1140069 | 300 | CTO | 880 | 652 | 607 | 356 | 23 | 455 | 100 | 122 |

| 21-350-781140069 | 350 | CTO | 880 | 652 | 607 | 356 | 30 | 455 | 200 | 122 |

| 21-400-78-0140069 | 400 | CTC | 880 | 652 | 607 | 356 | 30 | 455 | 250 | 223 |

| 21-400-781140069 | 400 | CTO | 880 | 652 | 607 | 356 | 30 | 455 | 250 | 223 |

3D drawings

Enquiry

Scroll for more info

Components

| 1. | Body | Ductile Iron GJS-500-7 |

| 2. | Bonnet | Ductile Iron GJS-500-7 |

| 3. | ISO flange | Ductile Iron GJS-500-7 |

| 4. | Stem | Stainless steel 1.4401 |

| 5. | O-ring | NBR rubber |

| 6. | Bushing | PA |

| 7. | Thrust collar | DZR brass |

| 8. | O-ring | NBR rubber |

| 9. | Seal | Hot melt glue |

| 10. | Bolt | Steel gr. 8.8, zinc plated, passivated |

| 11. | Key | Stainless steel A4 |

| 12. | Bolt | Steel gr. 8.8, zinc plated, passivated |

| 13. | O-ring | NBR rubber |

| 14. | Bonnet gasket | EPDM |

| 15. | Wedge nut | DZR brass |

| 16. | Wedge core | Ductile iron |

| 17. | Wedge shoe | PA |

| 18. | Wedge rubber | EPDM |

| 19. | Coating | Epoxy |

Test/Approvals

- Seat: 1.1 x PN. Body: 1.5 x PN.

- Drinking Water Inspectorate Regulation 31 compliant

Standards

- Designed according to BS EN 1074 -1 and 2

- Face to face according to EN 558 Table 2 Basic Series 3

- Standard flange drilling to EN1092 (ISO 7005-2), PN 16