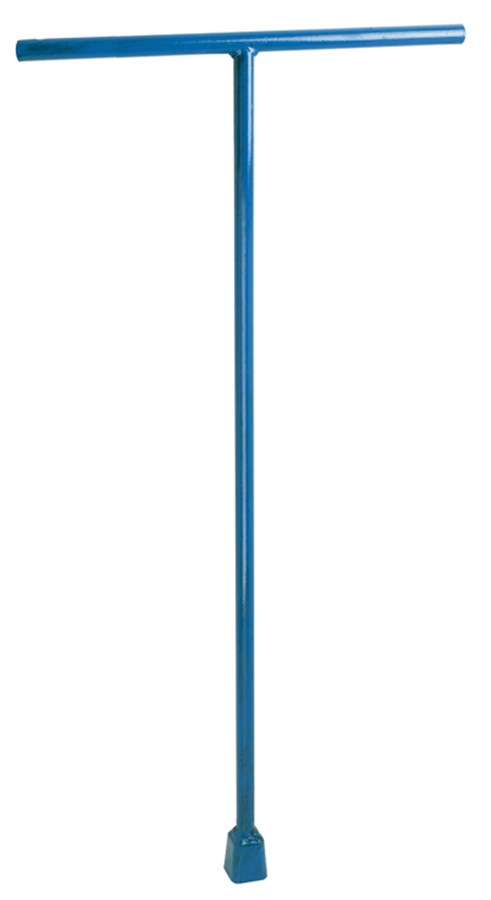

AVK GATE VALVE WITH PE PIPE ENDS, PE 100, PN 10

For gas, SDR 11 PE pipe ends, NBR wedge, CTC

Andy Hatton

National Sales Manager – Gas

Gate valve with PE pipes

AVK gate valves are designed with built-in safety in every detail and with full traceability of vital valve components. The wedge is fully vulcanized with AVK’s own oil and gas resistant NBR rubber compound. It features an outstanding durability due to the ability of the rubber to regain its original shape, the double bonding vulcanization process and the sturdy wedge design. The triple safety stem sealing system replaceable under pressure, the high strength stem and the thorough corrosion protection safeguard the unmatched reliability.

| Variant 36/90-170 | |

|---|---|

| Connection: | PE Pipe Ends |

| Material: | Ductile Iron |

| PN: | PN 10 |

| Closing direction: | Clockwise to Close |

Features

Fixed, integral wedge nut prevents vibration and ensures durability

Fully vulcanized wedge with guide rails, integrated wedge shoes and a large conical stem hole

Stainless steel stem with wedge stop and rolled threads for high strength

Full circle thrust collar provides fixation of the stem and low free running torques

Triple safety stem sealing with an NBR wiper ring and four NBR O-rings in a stem seal nut of dezincification resistant brass replaceable under pressure. A rubber manchette is the main seal to the flow.

Round NBR bonnet gasket fixed in a recess

Countersunk and sealed stainless steel bonnet bolts encircled by the bonnet gasket

Full bore

Low operating torque

Epoxy coating to DIN 30677-2 and AVK guidelines

A standard PE pipe is pressed onto the grooved valve end, locked with a steel ring and sealed with a plastic shrink hose. The boltless, full bore PE end connection is tensile resistant and stronger than the PE pipe itself. The PE pipe end enables direct welding into PE pipes resulting in a fast and secure assembly

Downloads

Components

| 1. | Stem | Stainless steel 1.4104 (430F) |

| 2. | Wiper ring | NBR rubber |

| 3. | Stem seal nut | Brass CW602N |

| 4. | O-ring | NBR rubber |

| 5. | Bonnet | Ductile Iron GJS-500-7 |

| 6. | Thrust collar | Brass CW602N |

| 7. | Shaft seal | NBR rubber |

| 8. | Bonnet bolt | Stainless steel A2, sealed with hot melt |

| 9. | Bonnet gasket | NBR rubber |

| 10. | Wedge nut | Brass CW626N |

| 11. | Wedge | NBR encaps. ductile iron |

| 12. | Body | Ductile Iron GJS-500-7 |

| 13. | Sleeve | Carbon steel |

| 14. | Shrink hose | Plastic |

| 15. | Pipe | PE |

Test/Approvals

- Hydraulic test to DIN 3230-5, PG 3 and en-GB 13774 class 2, Hydraulic test to DIN 3230-5, PG 3 and en-GB 13774 class 2, Hydraulic test to DIN 3230-5, PG 3 and en-GB 13774 class 2, Hydraulic test to DIN 3230-5, PG 3 and en-GB 13774 class 2, Hydraulic test to DIN 3230-5, PG 3 and en-GB 13774 class 2

-

Maximum Working Pressure: 7 Bar (100 psig)

- Approved according to DIN-DVGW Certificate NG-4313BO0281

- Approved according to DVGW EC Certificate CE-0085BO0317

- Approved according to ÖVGW Certificate G 2.711

- Approved according to SVGW Certificate No. 08-068-5

- Approved according to KIWA Certificate 65139/01

Standards

- Designed according to en-GB 13774